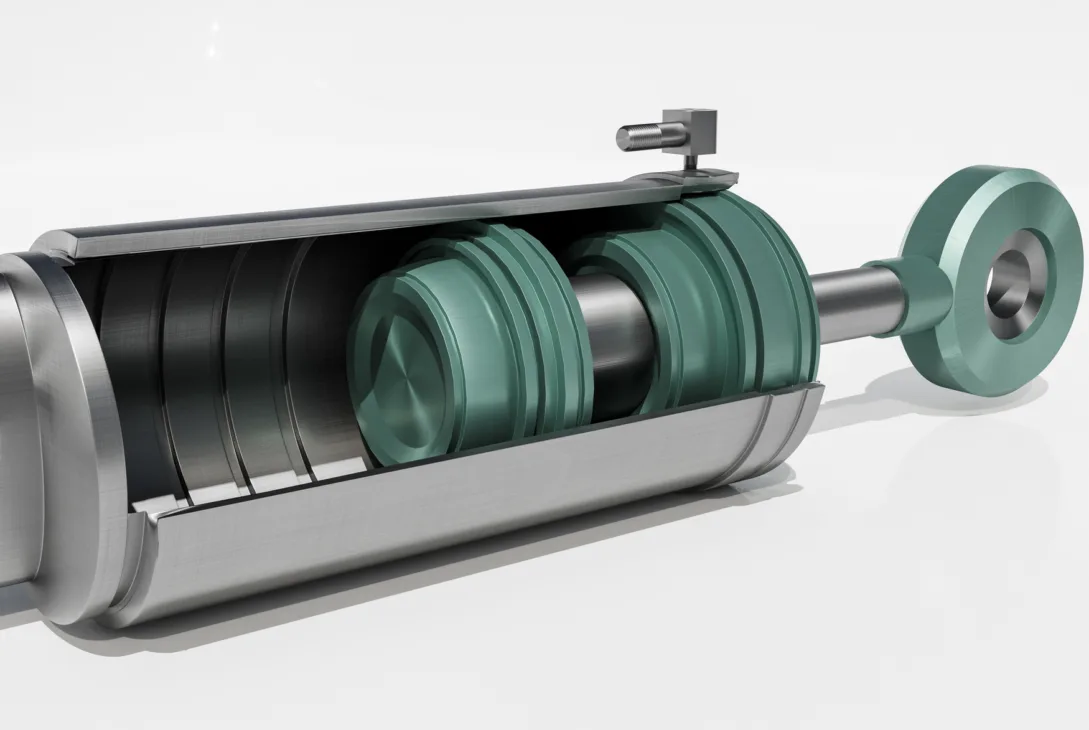

In various industries, efficient and reliable pumping solutions are paramount to enhance productivity. The progressive cavity or PC pumps are an effective choice for many applications. This article explores how progressive cavity pumps improve productivity by highlighting their unique design, versatility, and ability to handle challenging fluids. Progressive cavity pumps are positive displacement pumps that operate on the winding rotor and stator action principles. The pump consists of a rotor, typically shaped like a screw and a stator with a double helix cavity. As the rotor rotates within the stator, cavities are formed and progress along the axis of the pump, resulting in the movement of the fluid.

Consistent Flow and Pressure

Progressive cavity pumps provide a steady fluid flow with consistent pressure. This reliable and controlled flow is crucial in many industries requiring precision and accuracy, such as food and beverage, chemical processing, and oil and gas.

High Viscosity Fluid Handling

One of the key advantages of progressive cavity pumps is their ability to handle fluids with high viscosity. These pumps excel at transferring thick, dense materials like adhesives, slurries, pastes, and oils. By efficiently moving these challenging fluids, PC pumps improve productivity in industries dealing with such substances.

Shear-Sensitive Material Handling

Many products, such as delicate food ingredients or pharmaceutical formulations, are sensitive to shear forces. Progressive cavity pumps exert minimal shear, ensuring the material’s integrity and quality. This feature is particularly beneficial in industries where maintaining the product’s characteristics is crucial.

Solids Handling Capability

Progressive cavity pumps can handle fluids containing solids, including suspended particles or abrasive materials. The gentle pumping action of the rotor and stator prevents damage to the solids, reducing the risk of clogging and downtime. This capability is valuable in wastewater, mining, and sludge processing industries.

Versatility in Application

Progressive cavity pumps are versatile and suitable for various applications. They can handle thin and thick liquids, making them adaptable to various industries. Whether pumping paints, resins, sewage, or even food products like yogurt or chocolate, PC pumps offer reliable performance and enhance productivity.

Self-Priming and Reversible Operation

Progressive cavity pumps are self-priming, meaning they can evacuate air from the suction line and start pumping immediately. This feature saves time and effort during the startup process. Additionally, PC pumps can operate in both directions, allowing for flexibility in applications requiring reversible flow.

Progressive cavity pumps offer many advantages that significantly enhance productivity in various industries. Their consistent flow and pressure, ability to handle high-viscosity fluids, gentle handling of shear-sensitive materials, solids handling capability, versatility in application, self-priming, and reversible operation make them a reliable choice for pumping solutions. By choosing progressive cavity pumps, industries can optimize their processes, minimize downtime, and increase overall productivity.