Aluminium, nature’s lightweight champion, reigns supreme in countless industries. Its strength, adaptability, and conductivity fuel innovation across the globe, from sleek automotive structures to intricate aerospace components. Yet, even the most meticulously cast aluminium harbours a hidden foe – microscopic porosity. These tiny air pockets, though often insignificant, pose a veiled threat to long-term performance and reliability.

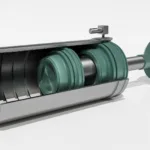

In a stroke of engineering brilliance, aluminium casting impregnation emerges as a game-changer. This cutting-edge process meticulously fills these minute voids, crafting castings that transcend limitations. Imagine aluminium components not just strong, but impregnable, impervious to even the most demanding applications.

A good aluminium casting company must require top-notch product quality development engineers to fully utilise their expertise and partner with you. The company also needed to utilise the latest CAD software and advanced mould flow simulation tools, to co-create a die-casting process specifically tailored to your needs. This collaborative approach optimizes yield, ensures impeccable quality, and exceeds even the most stringent product specifications.

Now, we have found the aluminium casting company which is Teknicast, your comprehensive aluminium casting partner, equipped to handle every step seamlessly. Their state-of-the-art facility advanced die-casting technology, followed by a comprehensive suite of machining services and aluminium casting impregnation solutions. This ensures casting aluminium parts are flawlessly machined and ready for the world, all within the same facility.

Teknicast boasts an impressive orchestra of 150 CNC machines, each wielded by skilled artisans. From the first cut to the final polish, your aluminium casting parts receive the expert attention they deserve. Unwavering quality control measures safeguard every stage, ensuring flawless deliveries and instilling confidence in the reliability and performance of every casting in aluminium you receive.

Now, we understand the importance of a flawless finish. Teknicast’s skilled artisans meticulously apply chromate treatment. This creates a beautiful, wear-resistant surface that elevates aesthetics and safeguards against the elements. Your aluminium casting parts not only perform flawlessly but also stand the test of time, a testament to Teknicast’s dedication to enduring quality.

From collaborative tool design to flawless finishing, Teknicast orchestrates a symphony of precision and efficiency. They are your one-stop partner for high-performance aluminium castings, delivering impregnable performance, unwavering quality, and peace of mind at every step. Let’s discover what service they provide can fulfil your company’s needs now!