Were you today years old when you knew about positive displacement pumps? Personally, we’ve never really understood much of it until today because of the intensive research we’ve done. First off, positive displacement pumps are a necessity in many industries because they are great at moving different fluids efficiently. This is done by moving a fixed amount of fluid with each turn, controlling the flow and keeping things running smoothly. For example, in manufacturing, they are used for dosing chemicals and transferring fluids. Meanwhile, in the oil and gas industry, these pumps are used to move crude oil and other products. They are also vital in areas like food processing, wastewater treatment, and pharmaceuticals. Have you noticed the similarities? Yes, they all handle fluids. Basically, these pumps are important for a lot of different processes.

What are Positive Displacement Pumps?

Positive displacement pumps are mechanical devices that transfer fluid by trapping a fixed amount and then pushing it out into a pipe. Unlike some other pumps that tend to speed up or slow down depending on how much pressure there is, these pumps keep a steady flow rate. They operate by creating a sealed space that gets bigger and smaller, pushing the fluid out. As you can see, these pumps are essential in a lot of industries because they can handle different types of fluids and ensure that everything flows smoothly in both machineries and systems.

Role in Various Applications

Positive displacement pumps serve pertinent roles in various industrial applications, contributing to smoother operations and efficient processes.

Fluid Transfer

Positive displacement pumps ensure that liquids are able to move around in factories and other places where things are manufactured. They help transfer fluids between different parts of the production process or within machines themselves.

Chemical Dosing

These pumps are pivotal when it comes to adding the right amount of chemicals in places like factories or chemical plants. They ensure that chemicals are mixed accurately and also applied precisely in the production process. In other words, they help maintain quality and ensure that everything is done properly during the manufacturing and processing of materials in industrial settings.

Fluid Transportation

For instance, in the oil and gas industry, positive displacement pumps are crucial when it comes to moving fluids such as refined products, crude oil, and drilling fluids through pipelines and facilities. They are essential for tasks like exploring for oil, refining it, and distributing it to where it’s needed. These pumps ensure that fluids are transported smoothly and efficiently as they play a huge role in the entire process of extracting, refining, and delivering oil and gas products.

Types of Pumps

Reciprocating Pumps

Reciprocating pumps work like a piston in a car engine. They move back and forth by pushing the pump forward and pulling it back in a repeated motion. These pumps can be found and are used when there is a need to measure or dose out fluids really accurately. For instance, in chemical mixing, and medical equipment.

Rotary Pumps

Rotary pumps, on the other hand, operated by using rotating parts like screws, gears, or lobes to move fluid from one place to another. They provide a smooth and steady flow, perfect for transferring a lot of liquid quickly. They are also often used in situations where you need to transfer a large volume of liquid, like lubricating machinery or pumping fuel.

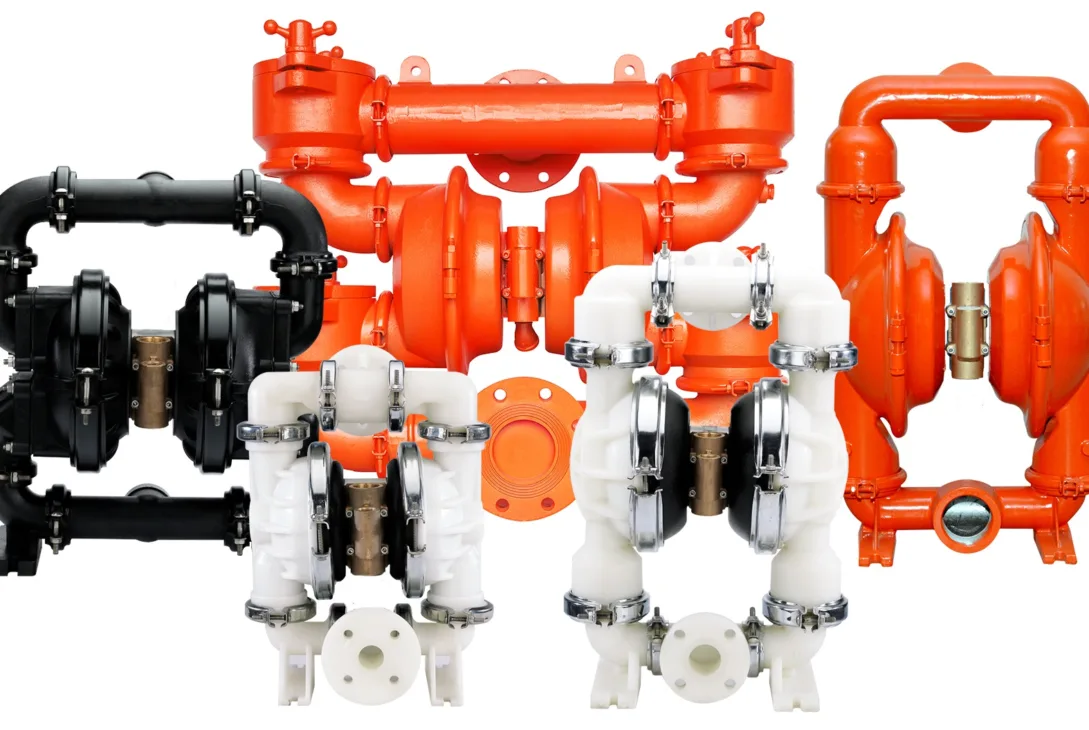

Diaphragm Pumps

Air-operated double diaphragm pumps are a special type of pump that uses compressed air to maneuver two flexible members, called diaphragms, back and forth. This movement creates suction and pushes fluid through the pump and is also great for handling different fluids gently. These are most commonly found in industries like food, chemicals, and pharmaceuticals. THey are versatile, reliable, and easy to maintain, making them popular in many applications.

Importance of Choosing the Right Supplier

Product Quality

A good supplier will make sure the pumps they provide are in top-notch quality. This means that the pumps will ensure that your operations are efficient and are also durable so you do not need to get them replaced. When the pumps are high in quality, they are less likely to break down or need fixing. This saves time and money on maintenance, making everything run a lot smoother and more efficiently.

Technical Support

Most of us do not have the necessary knowledge to operate these pumps. Hence, a reliable supplier will aid in setting up, fixing problems, and taking care of the pumps. They will also tend to give you advice as they do their best to assist with your conundrums.

Customization Options

Choosing a positive displacement pump supplier that supports customization options means you can get pumps that fit exactly where and what you need. Getting the pumps to work efficiently can be tricky sometimes because your supplier may not support the idea. However, a good one will be able to customize their solutions and ensure that you have the best fit.

Reliability and Durability

A supplier that wants to conduct their business for as long as it takes will provide their clients with products that are sturdy. This ensures that they are built to keep working for a long time. On top of that, they have to ensure their pumps use really strong materials that make them resilient so they do not break down unexpectedly which may cause issues in the long run.

Conclusion

After all, choosing the right supplier for your positive displacement pumps is really important. It ensures that your operations can run smoothly and efficiently. Most if not all industries require you to emphasize on quality and reliability when it comes to choosing a positive displacement pump supplier in Malaysia. It will help keep downtime to a minimum, prevent unexpected issues, and improve your operations. That’s why we prioritize these factors to cut down on maintenance costs and boost productivity.